1 / 3

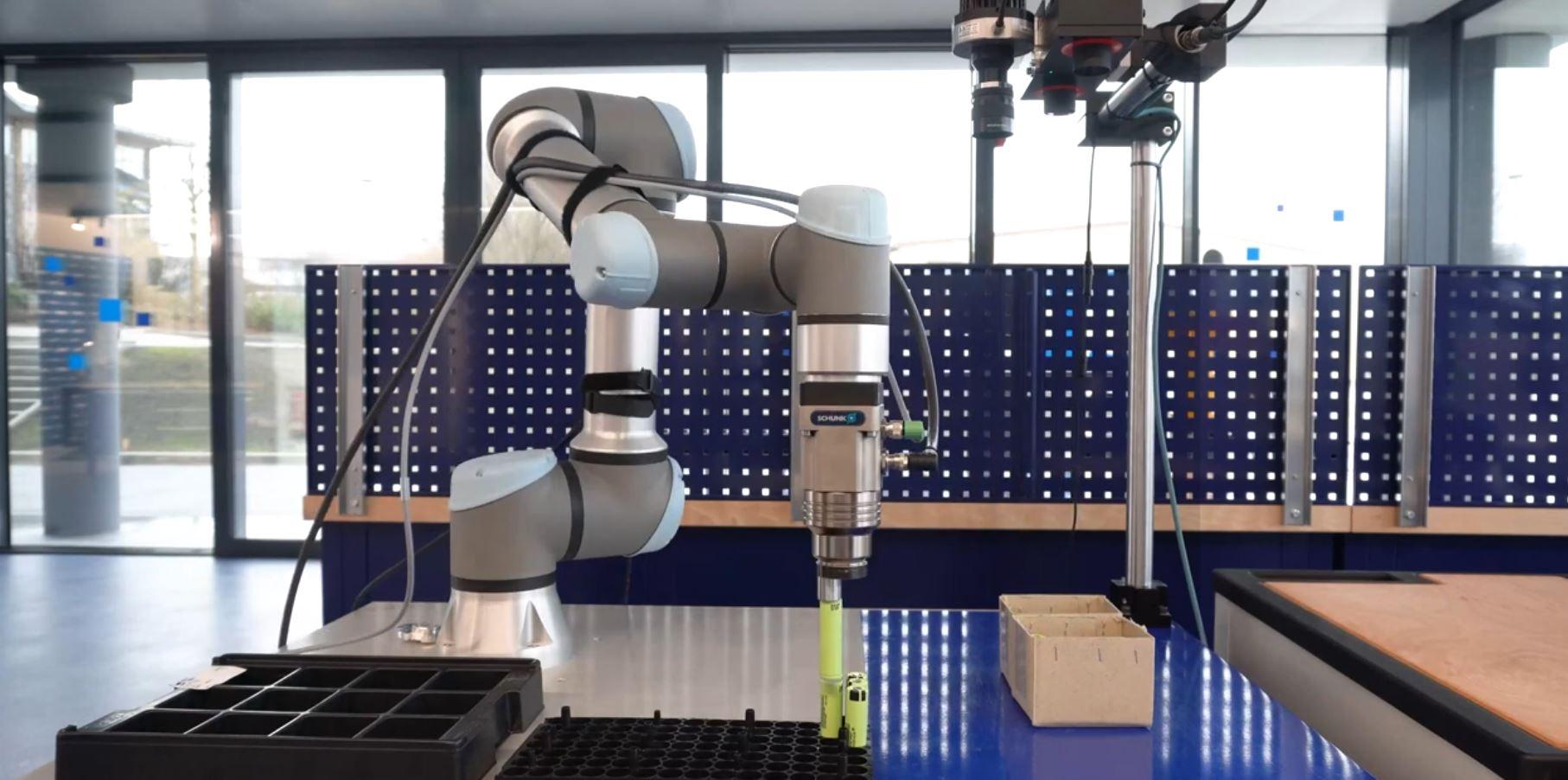

1 / 3Pick and Place mit dem Varioshaker 270 und einem FANUC Roboter

Hardware Price:

Dimensions

396x345x128

mm

Recommended part size

0.5 - 50

mm

Work space

185 x 185

mm

Robust Pick-and-Place Solution with Varioshaker and Vision Camera

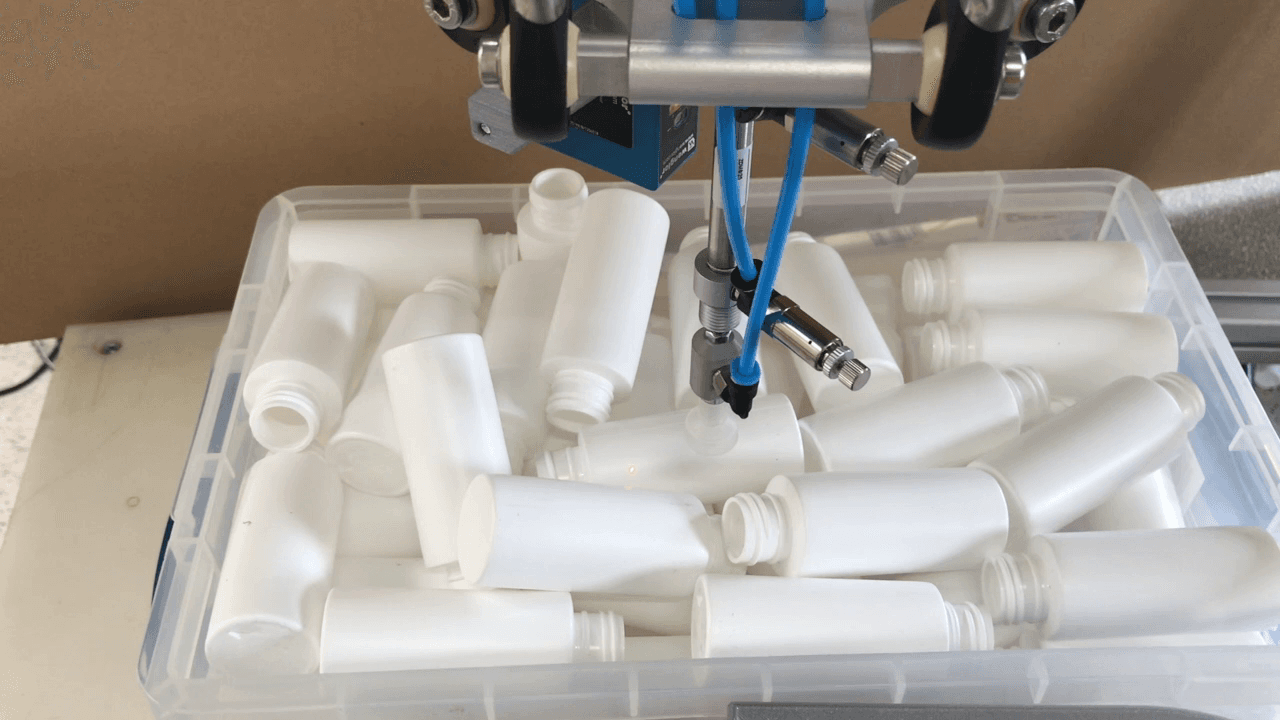

Efficient and precise handling of small components is crucial in modern manufacturing. This application by Variobotic demonstrates how industrial robots, combined with vision camera systems and the Varioshaker, deliver a reliable pick-and-place solution. The Varioshaker uses vibration to separate components, while the camera identifies their positions, providing the robot with the data needed to pick and place them accurately into fixtures.

What is the Application?

The system automates component separation and placement, ensuring accurate and efficient handling of small and varied parts. The robot operates based on real-time data from the camera, enabling seamless workflows.

What are the Advantages of the Solution?

High Precision: Ensures accurate part handling with minimal errors.

Improved Efficiency: Automates labor-intensive tasks to save time.

Versatility: Adjusts easily to different component sizes and geometries.

What are the Advantages of the Robot?

The industrial robot in the setup enhances automation with:

Seamless Integration: Works perfectly with the Varioshaker and vision camera.

Reliability: Operates continuously with consistent precision.

Flexibility: Adaptable to various applications and industry needs.

Optimizing Manufacturing with Pick-and-Place Technology

The combination of the Varioshaker, vision camera, and industrial robot delivers a scalable solution for manufacturing tasks. By automating component separation and handling, this setup enhances precision, reduces manual effort, and improves overall productivity, making it ideal for high-speed production environments.

2 Components